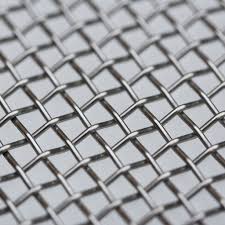

Woven wire mesh is a versatile and robust metal product, crafted by interlacing wire strands in a zigzag pattern. Its strength and durability make it ideal for a wide range of applications across industries such as construction, mining, agriculture, and manufacturing. From filtration and sieving to fencing, security screens, and insect barriers, wire mesh serves countless purposes. Available in various materials like steel, stainless steel, and other alloys, it adapts to the specific demands of different environments and industries.

Types of Weave

Wire mesh can be woven in several different ways to create different patterns and densities. Here are some of the most common types of weave:

Plain weave: This is the simplest and most common type of woven wire mesh. In plain weave, each wire alternately passes over and under the adjacent wires in both the horizontal (weft) and vertical (warp) directions.

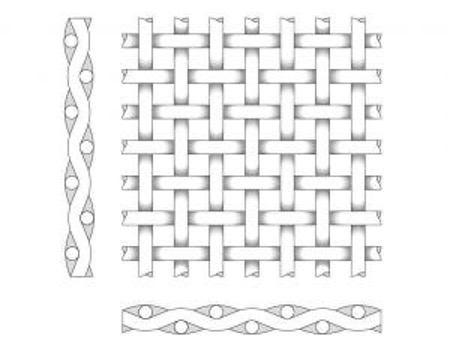

Twill weave: This type of weave creates a diagonal pattern in the mesh. It is formed by passing each weft wire alternately over two and then under two warp wires. This weave creates a tighter mesh with a higher wire count per inch, making it ideal for filtration applications.

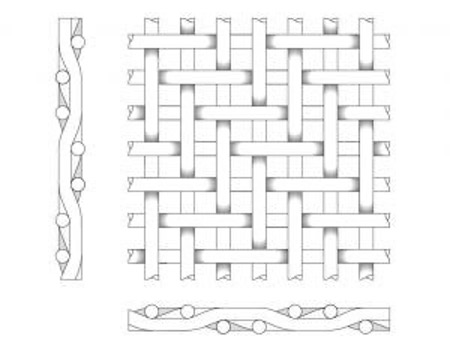

Dutch Weave: This type of woven mesh features a higher wire count in the warp direction compared to the weft direction. By using thicker warp wires and thinner weft wires, it creates a smooth, dense surface ideal for filtration. Dutch weave mesh is particularly effective for applications requiring the filtration of fine particles. There are two variations of Dutch weave: Plain Dutch weave, which has thicker warp wires and fewer weft wires, and Twilled Dutch weave, which incorporates a greater number of weft wires for an even denser and more refined mesh.